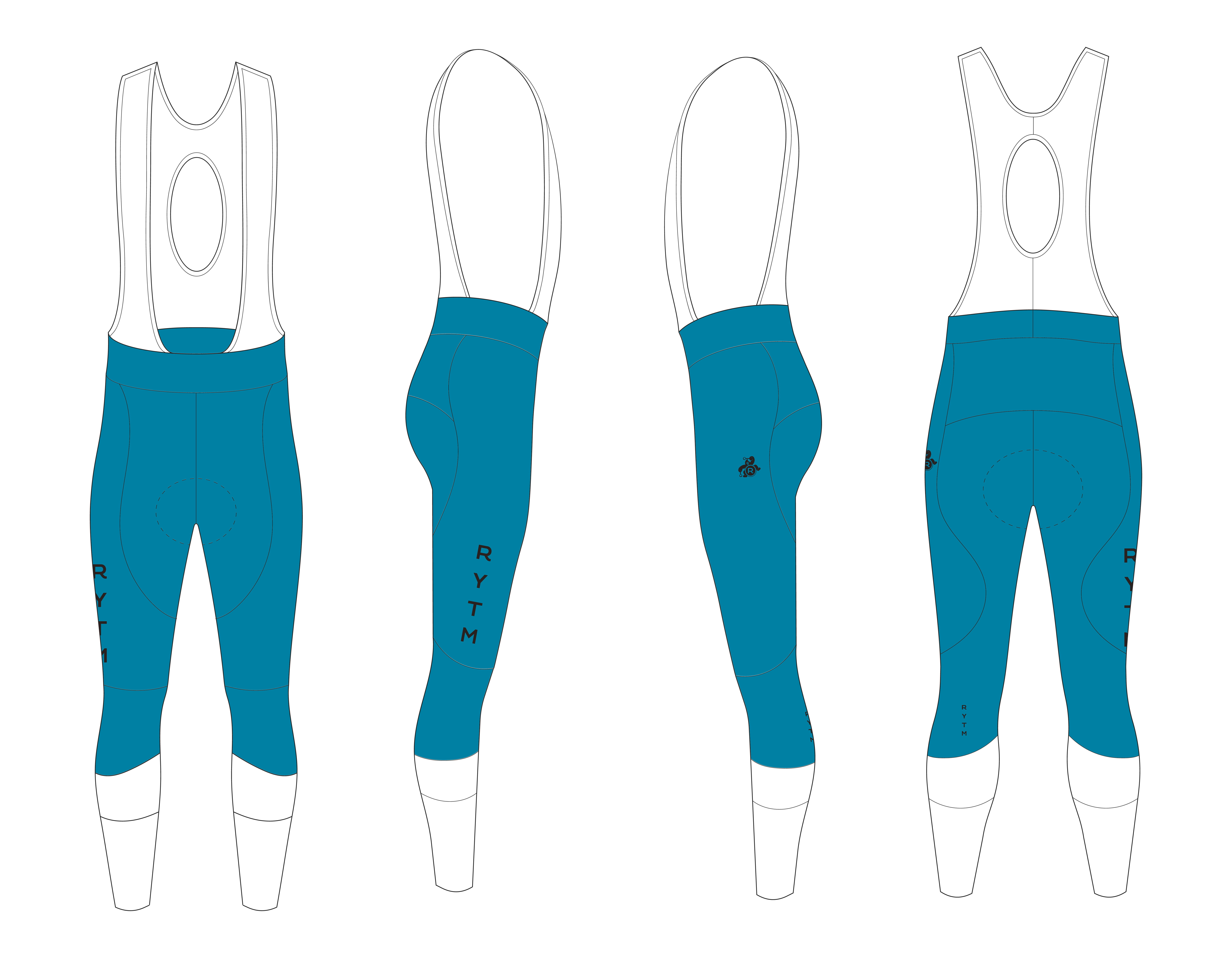

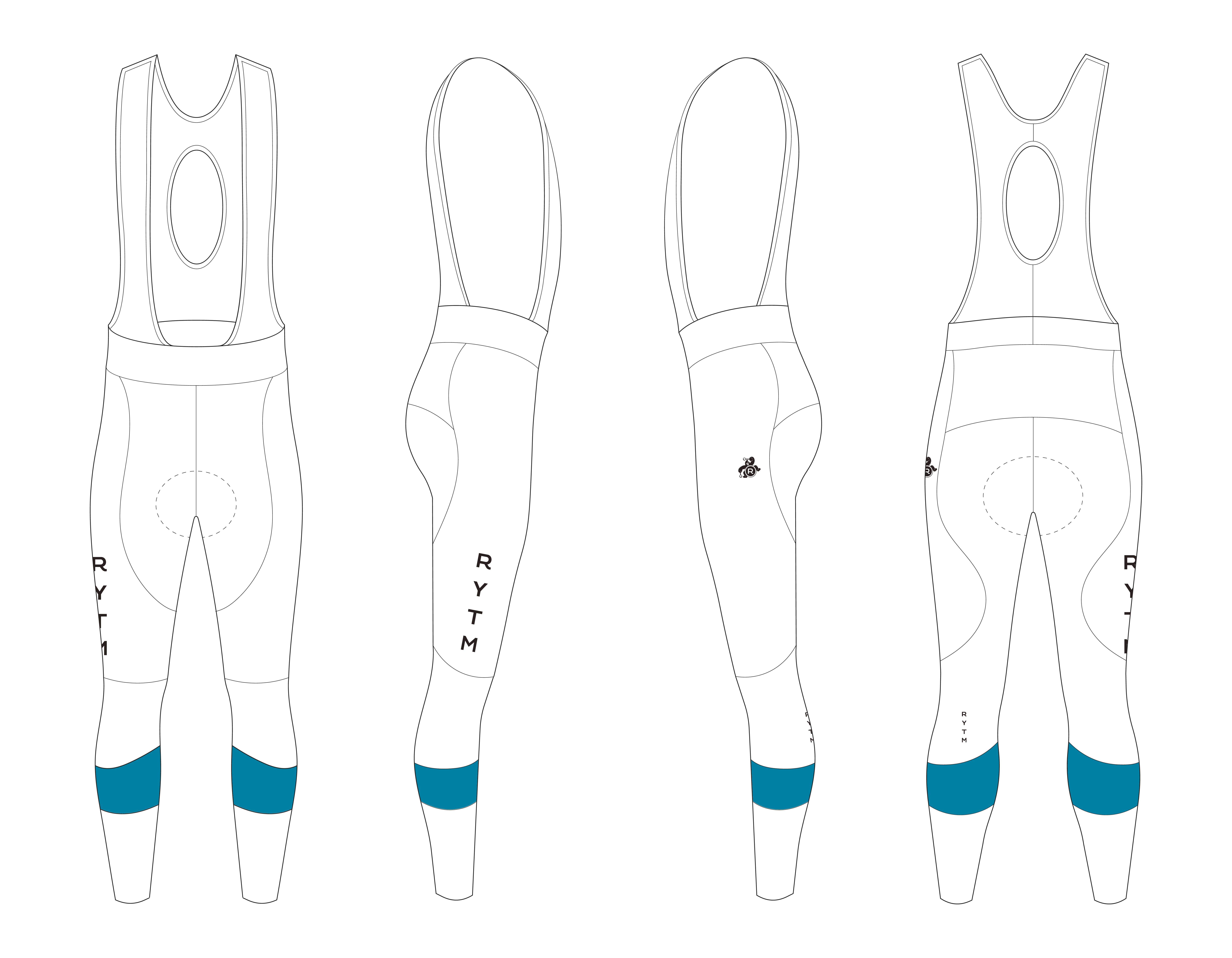

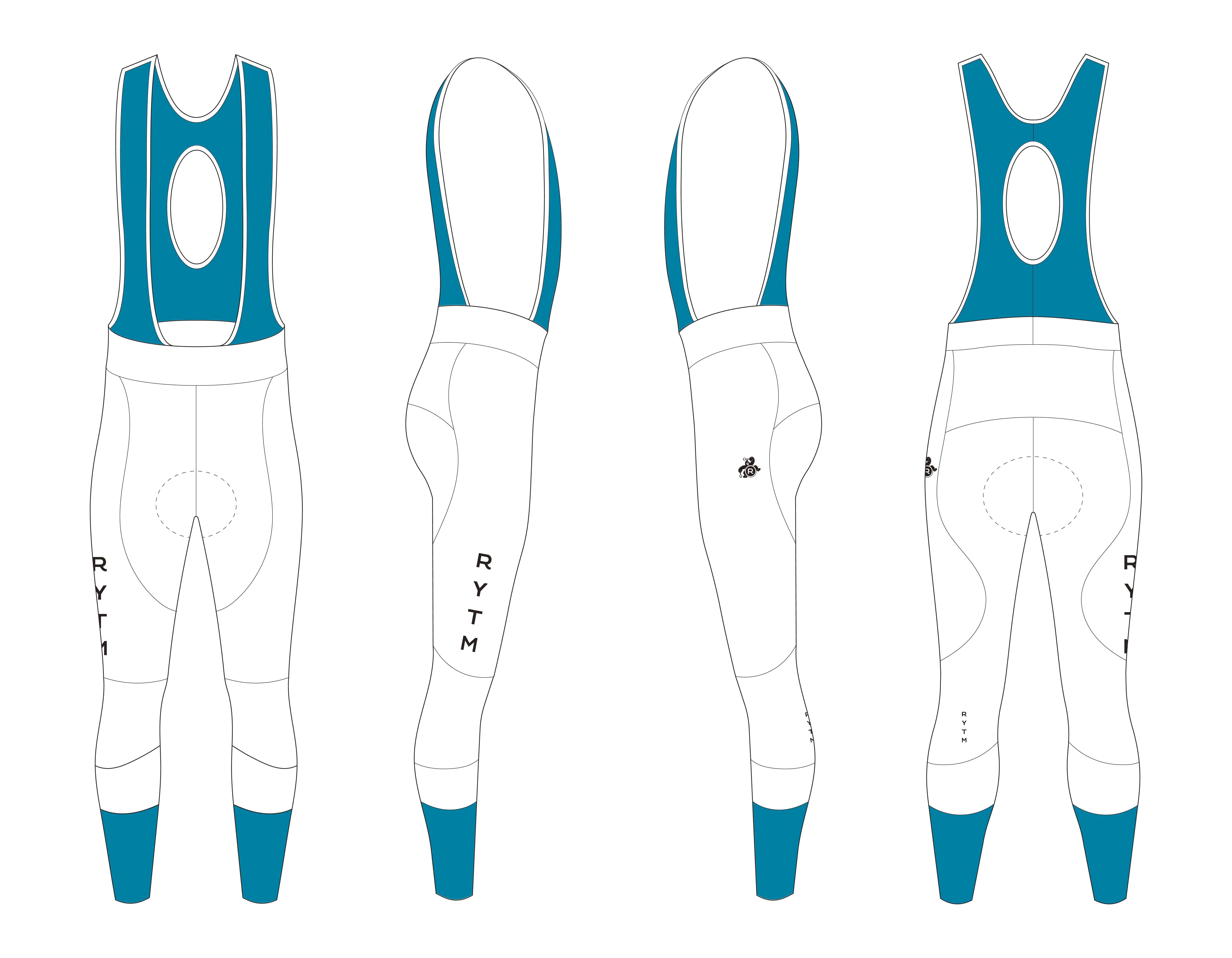

Veloce Winter Tights

—— Solid Black€100,00

The main fabric of our Veloce Winter Tights is Thermoroubaix Checkmate and the name says it all. Whatever the weather brings, whatever the road looks like, those tights with our Italian high technological pad are made to ride on and on, without ever losing your rytm.

Every zone of your body has other needs for optimal performance. We developed a body map panel system, resulting in a garment that is suitable for every part of your cycling body. Our Veloce Winter tights have 3+1 fabrics.

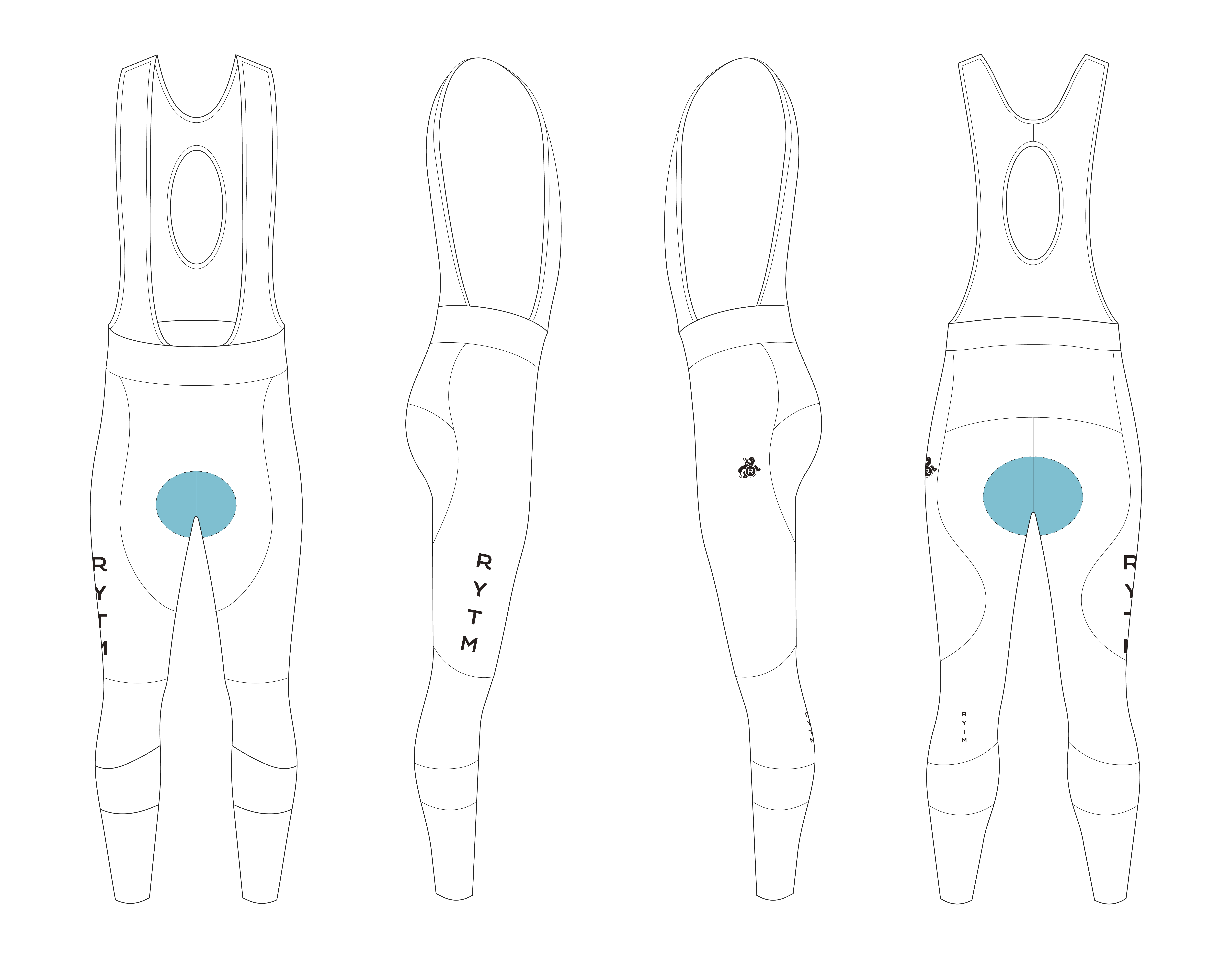

The perfect Chamois is a thing of beauty and exceptional comfort. Creating it is such a complex craft that we wouldn’t dream of making it ourselves. We luckily found the best padbuilders in the world.

We liked them instantly, because they hate the word ‘content’ as much as we do. These relentless Italian perfectionists create a Chamois from the stuff legends are made of. They design, carve, perforate and build pads for the most demanding PRO riders. With a super-focus on their unique product, they keep innovating so that riders like you can super-focus on going faster. When you need all the power in your body to push your own limits, a little comfort where you need it most is a fantastic booster.

These Chamois are designed to disappear from your mind as soon as you put them on. None of the iconic champions in those historical races remember wearing them, and neither will you when you’re wearing your Veloce bibs and Veloce tights. On a bad day, you can blame the weather, that glass of wine the night before or the mosquito in the room, but you’ll never blame the Chamois.

— Read all about our chamois scrolling further.

All fabrics of the Veloce Winter Tights are Italian and UV-protected.

Main: PA 83% - EA 17%

Italians love cyclists. They cook the best spaghetti, they make espresso, they shaped the Stelvio and they produce the most advanced cycling fabrics in the world. And that’s why we love to work with them and to push their magical skills a little further every time.

The BLUESIGN® Approved label ensures that the Rytm apparel is made from fabrics and materials that are produced using only chemicals and processes that are safe for the environment and people.

This is done by minimising water usage and emissions during the manufacturing processes. BLUESIGN provides safer and more sustainable environments for people to work in, and for everyone to ride in. With a holistic approach, BLUESIGN traces each textile’s path along the manufacturing process, making improvements at every stage from factory floor to finished product. BLUESIGN changes the environmental impact of textiles for good. As a solution provider and knowledge broker, BLUESIGN acts as an independent verifier to secure trust and transparency. Corresponding to this approach, BLUESIGN encourages the industry to increase their efforts in sustainable processes step by step.

Ride the blue way.

— Highest degree of safety for the consumer.

— Manufacturing with lowest possible impact on people and the environment.

— Responsible use of resources.

Molded to your body on the inside.

And to your saddle on the outside.

Whatever your gender or shape, there’s a Chamois for you.

Our chamois pads have antimicrobial properties to reduce odor and bacteria.

The chamois was originally a piece of soft leather from the chamois goat-antelope. It was used for cleaning and shiny finishes. We still like to use this term for the pad in our bibs and tights for different reasons: a chamois loves to climb, it’s fast, it’s soft and it makes you shine.

Nowadays, the chamois we use is made of premium fabrics and perforated foams of varying densities and four different layers, each with their own functions. The top surface helps to wick moisture. Because it comes in direct contact with your skin it’s also the sofest layer. Under this ‘luxurious’ layer, are the more technological layers. The upper with it’s fast-drying and breathable materials is designed to fit your body contour perfectly, while the high-tech underneath padding features geometric lines created to perfectly match the saddle. Our 3+1-dimension pad alleviates pressure and gives ultimate comfort for your most sensible zones.

Our goal is to give you optimal comfort and eliminate all friction and unpleasant feelings in the zone that carries all the weight. Our chamois is engineered to keep the rytm for short and long high-intensity rides. We even extended the pressure zone for optimal support for those long climbs because the body position and the pressure on the sit bone is slightly different when going up-hill.

Our pad is made with premium fabrics to raise the quality standard and increase your enjoyment. First, we started considering what is necessary: friction, sweat, and irritations are evils to be eliminated.

Men and women have a different anatomy and so do our chamois. The women's version has a wider foam placement in the sit bone area to provide continuous comfort through the central region. The men’s chamois is moulded with a central channel to increase blood flow. This to reduce pressure and numbness while riding.

100% of positive feedback.

The chamois we use in our Rytm bibs and tights are considered as the perfect pad for pro riders, with a 100% rate of positive feedback. This pad was and still is carefully perfected to reach its final shape to become the top one in performance, functionality, and precision with no compromises through the years.

Read about the technology, fabrics and foams we use to achieve our goal so you can achieve yours.

The latest upgrade was made by adding 3D Wings on the sides to increase the comfort and allow the pad to contour the legs. Thanks to its perfect combination of an aggressive design for elite performance and high comfort on long distances all in one, this pad is the first choice of many pro riders and amateurs who want the best to push hard.

We use 3D CELLS fabric. It is a soft and stretchy microfiber fabric with embedded breathable cells that make the fabric very recognizable. The 3D cells are the main characteristic of this fabric, as they ensure perfect moisture management and airflow.

The other fabric that is used in our pads has a proven record for a decade. Its performance makes the difference. The key factor is the structure of the fabric; it is warp knitted with high abrasion resistance and two-way stretch.

All the premium fabrics are laminated only with premium reticulated and open-cell polyurethane foams. The exclusive use of high-quality foams is essential to provide the rider with the most dynamic response, comfortable support for many hours, elasticity, breathability, and durability, all in one. Discover the three versions we have developed over years of tests and with feedback from thousands of professionals and amateurs: riders from all over the world who helped us define the three best groups to cover 100% of anatomic variables.

Each of our three performance density foams is laminated exclusively with medium-density foam as the intermediate layer between the fabric and the performance padding.

This reticulated foam offers unique moisture management properties, increased breathability, and a softer feeling on the surface.

Carving technology is the procedure that removes excess material where it is not needed. It eliminates stiff areas to ensure absolute comfort. Through variable compression, the mold deforms the foam while a razor blade removes the unnecessary parts, leaving just the needed amount of foam. This creates differentiation between the comfort density and the performance density, avoiding stiffness in pressure areas and channels and enhancing breathability and durability as well.

While the seat pad is being thermoformed, any edges are compressed and cut to cover the foam around the seat pad’s perimeter. This technology allows for any type of stitching, eliminates all chafing and, through minimalism, allows us to reach aesthetic perfection. Looking good!

The sense of fatigue often comes from irregular blood flow. How can this aspect be improved? Sometimes high quality is not enough. The Elastic Mesh Cup was conceived to allow for regular blood flow in the sensitive areas while riding, thanks to a perforated and comfortable housing designed to hold the male privates in an elastic zone, keeping them dry.This brand-new way of modeling seat pads supports performance because it eliminates the sensations of fatigue and sweat we feel with products that cause constant compression in such a delicate area. Thanks to the greater elasticity, this technology also ensures a more natural fit between the seat pad and the bibshort.

A simple idea that has impact on your rides. While carving technology can be considered the best innovation in the development of the seat pad, it exposes the backing foam to direct, unprotected contact with the Lycra, increasing the friction between the seat pad and the short’s Lycra, therefore creating uncomfortable ridges. Some producers try to prevent this by attaching to the backing foam a basic polyester laminated with polyurethane film, but this reduces breathability by more than 80% and also decreases the flexibility of the seat pad. The P.B.C. (Perforated Backing Cover) is made with technical, super-elastic Lycra, which we perforate; this does not at all affect the overall breathability and also maintains the natural flexibility of the seat pad. The high durability of its structure allows the pad to glide smoothly with the bib short, perfectly following the movement of the leg while pedaling.